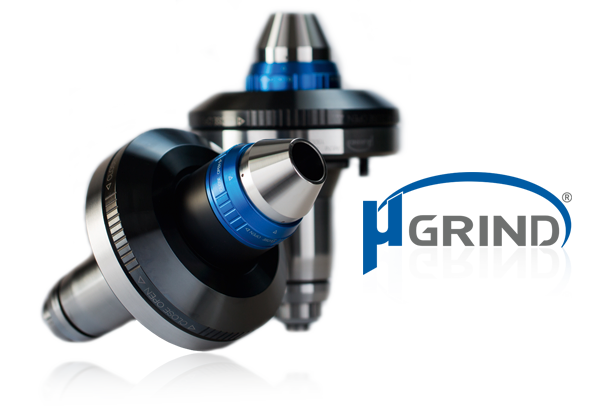

GDS μGrind series – Revolution in toolgrinding.

- Tapered profile for optimal wheel clearance

- Very high concentricity and repeatability, runout under 0.002 mm at 2½ x D

- Wobble alignment

- Concentricity alignment

- Change diameters in seconds simply by changing sleeves/collets; no adjustment needed

- Requires a relatively short clamping length on the blank to achieve constant holding force and concentricity

- Excellent dampening properties with very low wear; performs for tens of thousands of clamping

- Suitable for both high production and regrinding

We developed the μGrind in close cooperation with leading tool grinding professionals specifically to achieve high precision clamping in that field. Excellent damping properties for uniform material removal while optimizing feed rates. Workpiece surface finish is perfectly consistent and grinding wheel wear is significantly reduced. Your grinding process will be both highly productive and predictable.

µGrind series

Setup with micron-level accuracy in just a few minutes using two gauges, with absolute repeatability when changing blanks or collets (to change diameters)