The last piece in achieving production precision, efficiency, and cost effectiveness is a comprehensive balancing system.

- Easily detects an imbalance of less than 0.1g on small parts whether the part weighs 50 g or 8 kg

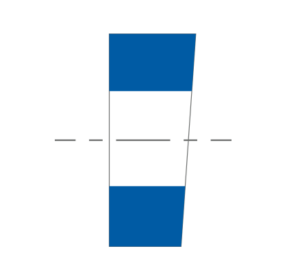

- Soft bearing balancing station. Light enough to move without special equipment

- Self-sufficient. No additional computers required

- Requires no PC or programming knowledge to operate

- Helps prevent spindle bearing damage and thus lowers operating costs

- Balances every tool or wheel set

Tool balancing increases tool life and improves tool performance

Wheel balancing increases wheel life and produces a better surface finish and cutting edge on the tools you grind

A GDS balancing system will not only help you grind better tools, it will also reduce grinding wheel wear and machine repairs. Equi’Z balancing improves the mechanical stability of your grinding machine and reduces stress on the grinding spindle.

Protect your grinding spindles and increase wheel life economically with precision balancing. You will also grind more tools per wheel and improve surface finish, which means happier customers and possibly higher margins.

IMBALANCE FACTORS

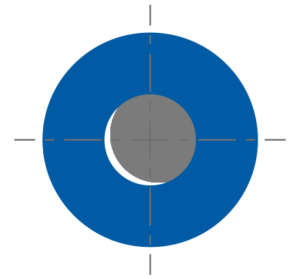

Tolerance of the grinding wheel bore

Imbalance consequence:

Reduced surface quality (chatter)

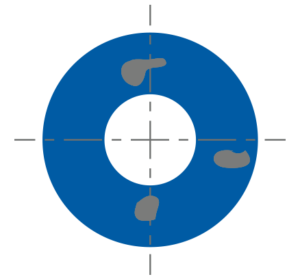

Homogeneity of the grinding wheel

Imbalance consequence:

Reduced dimensional accuracy of the workpiece and increased dressing costs

Parallelism of the grinding wheel

Imbalance consequence:

High grinding wheel wear (short service life)

Concentricity of the grinding wheel

Imbalance consequence:

Spindle wear (unnecessary repairs and machine downtime)